Html code will be here

Optimisation of Grinding Circuits

The Conundrum Process Control Solution for a grinding circuit is designed for the realisation of maximum performance of the circuit while simultaneously maintaining optimal requirements for product quality. The integrated system can work both in advisory mode and in automatic mode.

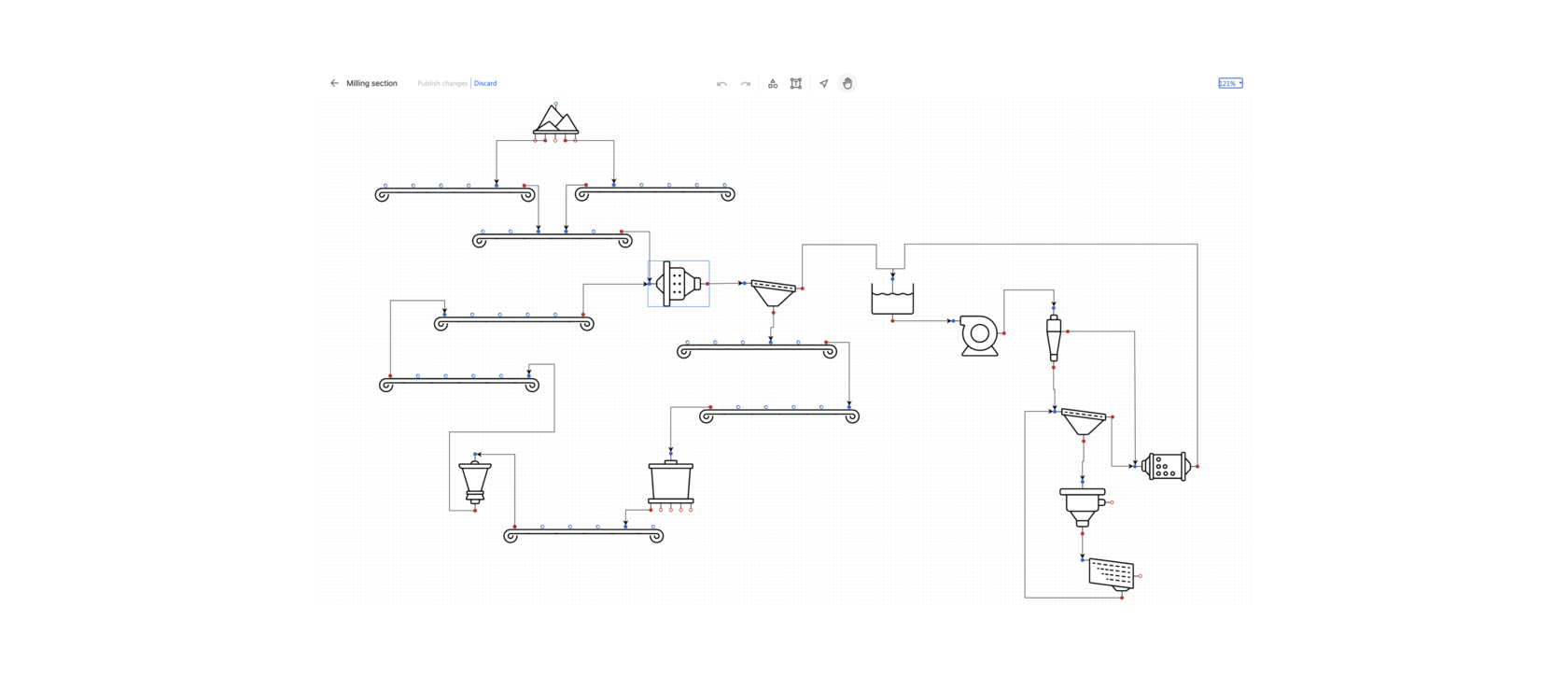

Example of grinding circuit

Challenge

These factors can lead to losses in processing potential and a reduction in overal performance of the circuit, especially:

Losses resulting from suboptimal use of available potential in the equipment

Higher consumption of energy, water and other consumables (balls and others)

Control instability: overloads, emergencies, shutdowns, defects, and more

The control of grinding circuits is complex, with many factors to account for:

A high degree of variability and volatility in the grinding processes itself

Natural irregularities in ore properties with no means of gathering operational information about it

No means for obtaining direct information about the current operating modes of equipment

Variability in management control resulting from operational regime (shift change, maintenance schedule and other factors)

Opacity of constraints imposed by sequential alterations in ore in each step of the circuit

Variability in equipment design, capacity, and performance as well as amortisation (mill lining and other factors)

- Determines and predicts the mode of operation of the grinding circuit and individual equipment units;

- Predicts potential emergency situations;

- Evaluates and takes into account the wear of the lining;

- Evaluates the possibility of additional loading of the grinding circuit;

- Performs predictive control on parameters with manual settings (power, speed, etc.);

- Performs predictive control on the operation of feeders to stabilise the power supply and minimise discrepancies;

- Determines optimal proportions from feeders to supply required granulometric composition.

ntelligent APC — responsible for the control and stabilization of the grinding circuit

To identify the optimal control system for the circuit, Intelligent APC:

How Intelligent APC works

- The current maximum allowable setpoint, taking into account the quality of the ore and the state of subsequent circuits;

- The refined quality of ore from circuit to circuit depending on their settings;

- The effect of planned treatment on the stability of the circuits;

- The effect of gradual wear of the equipment on the calibration of the control system settings;

- The manner in which discrepancies in sensor readings are taken into account;

- The way in which the design of the process scheme and changes during operations are taken into account.

Plantwide Recipe Adviser — connects the grinding circuit with the operation of the entire plant, takes into account ore properties and throughput of consecutive stages, and controls the entire circuit with recommended power settings and operating modes

To facilitate the optimal functionality of the Intelligent APC system, the Plantwide Recipe Adviser identifies the optimal system settings in response to the following:

How the Plantwide Recipe Adviser system works

Real time plant diagnostic — responsible for the quality of incoming data, as well as for recommendations on retrofitting the circuit in order to improve its efficiency

- Assesses the quality of available data and warns of their degradation;

- Provides recommendations for upgrading the circuit by installing additional sensors or equipment in order to improve throughput and management efficiency.

How the Real time plant diagnostic system works

The Conundrum system works with all types of grinding circuits and can realise improved efficiency even with incomplete mounting of sensors

Solution Visualisation Screen

Results from integration of the Conundrum system

Upto 60% reduction in the variability of indicators

1−3% reduction in energy consumption

Downtime prevention

2−5% increase in average hourly throughput

Industrial AI for metals & mining

Copyright © Conundrum Industrial Limited, 2024

Platform

CONUNDRUM INDUSTRIAL LIMITED,

Merlin Place, Milton Road, Cambridge, United Kingdom, CB4 0DP

Merlin Place, Milton Road, Cambridge, United Kingdom, CB4 0DP

CONTACTS

company

Contact us

By clicking the "Submit" button, you agree to the privacy policy